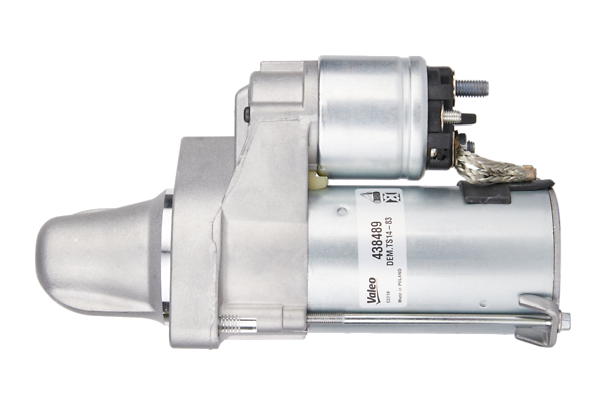

Starters for LCVs

Valeo New & Standard Exchaneg Starters – Innovation and high performance machines for premium comfort

With leading expertise and strong O.E. presence, Valeo provides a wide range of premium performance and quality starters to the Aftermarket. Valeo latest generations of starters are developed with high-quality components improving lifetime, reliability, comfort and efficiency. More than 400 references are available, including the latest technologies fitted as O.E. on latest car models, such as Peugeot 208, Renault Clio IV and Volkswagen Golf VII.

In addition to its new units benefiting from its O.E. expertise, Valeo has developed a complete premium Standard Exchange offer for starters. It covers almost all applications and meets car makers' requirements. With 30 years of experience in remanufacturing, Valeo is able to remanufacture all technologies available on the market. Valeo’s perfect knowledge of O.E. specifications enables a perfect and mastered assembly.

Valeo drives innovation, with more than one century of experience in rotating machines, from conventional starters to latest generation compacts and reinforced starters. The Valeo new starters range provides high standards of performance and quality to ensure premium customer satisfaction. The reliability, the safety and the best quality of new products are driven by constant innovation and high quality testing criteria.

Thanks to its strong O.E. presence, Valeo is able to offer starters for the latest car applications in a short time to market, such as for Peugeot 208, Renault Clio IV and Volkswagen Golf VII. Speed, temperature and electrical measurement tests are run up to 40,000 cycles to ensure the performance and reliability of new Valeo starters. In addition, the machines are submitted to extreme conditions tests such as salt spray, thermal shocks and vibration until destruction to meets the highest car manufacturers' requirements.

Valeo answers all markets needs thanks to a large range of technological evolution: permanent magnets or wound field inductors, reduction gears, shock absorbers, pinion-out starters for diesel applications are some examples of technical features developed according to specific application requirements. The last generations of starters, such as the TS and the TSC, provide higher power and efficiency in a more compact design than previous solution starters. This allows an easier integration into the engine environment without reducing the performance. This technology applies for Ford, PSA, Volkswagen or Renault-Nissan. With more than 800 references available, the Valeo Premium Standard Exchange offer features starters that cover all applications, both European and Asian. Through its strong O.E. presence and its time-to-market sensibility, Valeo is able to provide the aftermarket with the Standard Exchange solution for all starters fitting very recent car applications as the last Volkswagen Golf VII, Audi A3 or Renault Clio IV. Valeo's 30 years’ experience in remanufacturing and its O.E. expertise mean a specific fully mastered remanufacturing process for starters.

The specific remanufacturing process for starters enables Valeo to deliver products with the best quality standards. Once a starter is collected as core in the market, the part is sent to a specific production unit to follow the different steps of the remanufacturing process.

- After disassembling, all components are washed and blasted.

- Each pinion drive is inspected and possibly replaced by a new one with a 100% O.E. grease. Worn components they are automatically replaced. Brackets remanufacturing can be done if the component is out of tolerance. Valeo can ensure design and fitting conformity thanks to O.E. technical drawings.

- Dedicated test benches, which allow simulation of the ignition phase, are used to inspect the solenoid.

- The commutators of the armature are replaced if necessary in order to restore the O.E. electrical performance.

- Valeo has the capacity to replace or re-magnetize magnets through specific processes, ensuring improved durability.

Before final painting, all renovated components are reassembled and each complete product is tested on a mechanical test bench (Speed and temperature measurements, over tension conditions or destruction tests). O.E. standards are scrupulously respected during the whole process. O.E. test benches and measurements tools are used to validate the parts throughout over 40 checkpoints. Once assembled, 100% of the parts are re-tested under the same conditions, before being labelled and packaged. All Valeo remanufactured starters are 100% asbestos free.