Automatic Levelling Device for Car Headlights

The low beam must be adjusted at every headlight change or repair.

The risk of a bad adjustment can include:

- Dazzling oncoming drivers (1% error in headlamp aim multiplies dazzling 20x)

- Lack of driver visibility (1% error in headlamp aim = 20x worse lighting efficiency at 50 metres)

Older Halogen headlamps used manual headlamp levelling devices, so adjustment had to be done directly on the headlamp with a screwdriver. No switch was installed on the dashboard.

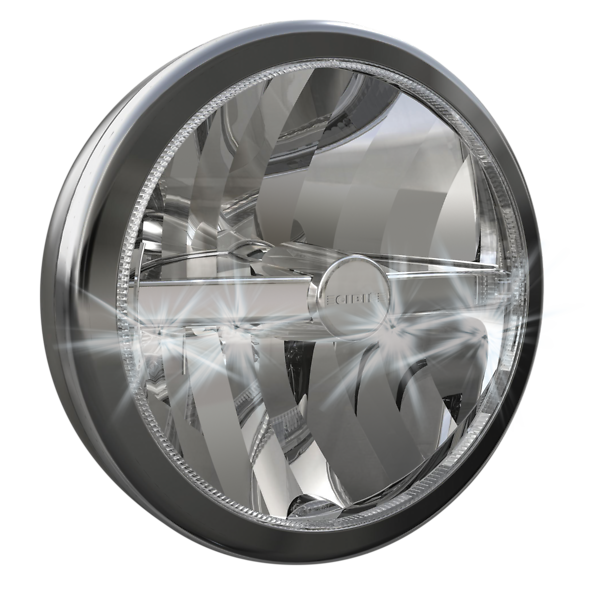

Xenon lamps generate such a bright light that even dipped lights can dazzle, so further regulation was passed to improve their design.

This is why Xenon systems must be fitted with an automatic levelling device to ensure lights illuminate at the correct level regardless of vehicle load.

Whereas quartz halogen systems can be fitted with manual (driver-controlled) levelling, Xenon systems must be auto-levelling.

This requires additional parts like suspension sensors to detect the need for position change and electric stepper motors to change the position physically. All of these systems are controlled by a lighting ECU.

The low beam must be aimed within a certain range (between -0.5% and -2.5%)

Legislation requires 6 different beam positions (depending on vehicle load.)